Requête

Lorsque nous recevrons votre demande, nous vous enverrons par courrier électronique dans les 24 heures les catalogues personnalisés, les tables de prix,

les conditions de livraison, les conditions de paiement et les autres informations nécessaires.

projet Grinding Mineral

Grinding and Flotation Optimization Using Operational

2019年1月11日 A strategy of classifying data for on-line generation of insights to using operational intelligence tools is described. The implementation of a recovery/grind

Consulter un spécialiste

Energy Use of Fine Grinding in Mineral Processing - Springer

2013年12月18日 Abstract. Fine grinding, to P80 sizes as low as 7 μ m, is becoming increasingly important as mines treat ores with smaller liberation sizes. This grinding is

Consulter un spécialiste

Reduction of Fragment Size from Mining to Mineral

2022年10月4日 The effects of rock fragmentation on the whole size reduction chain from mining to mineral processing are described. The main factors influencing rock

Consulter un spécialiste

Fives Project management for cement and mineral grinding ...

Fives is renowned for its extensive experience in industrial plant project management and EPC contracting for the cement and mineral grinding industries. As an industrial

Consulter un spécialiste

Ore Pretreatment Methods for Grinding: Journey and Prospects: Mineral ...

2018年6月18日 This review reveals that a variety of stress-generating techniques have been used to treat the composition and morphology of particles to improve the grinding

Consulter un spécialiste

Minerals Special Issue : Grinding Modeling and

The grinding process, as a primary stage of ore/raw material processing, is a necessary operation in beneficiation plants. It not only provides the appropriate particle size for subsequent separation operations but also

Consulter un spécialiste

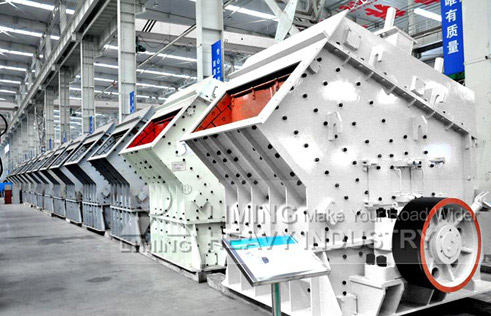

Mineral Processing Project Plant and Mineral Grinding Plant

Chanderpur Works is the leading manufacturer supplier of mineral processing plant, mineral grinding plant mineral beneficiation plant. CPW provides services to mining

Consulter un spécialiste

Tuning the Morphology and Surface Property of

2017年11月18日 Grinding of minerals for particle size reduction and liberation is a prerequisite for successful mineral flotation separation and powder modification. Different grinding media produce mineral particles

Consulter un spécialiste

Review on advances in mineral processing technologies

2022年4月1日 Mineral processing involves the liberation and concentration of economical metals and minerals from mineral resources for metal extraction (Lottermoser, 2010).

Consulter un spécialiste

Integrating online mineral liberation data into process

2021年9月1日 These results confirm the importance of considering mineral liberation explicitly into control and optimisation strategies, as it is the direct link between grinding

Consulter un spécialiste

projet grinding mineral - lopescofi

2019年5月6日 The process of froth flotation entails crushing and grinding the ore to a fine size. This fine grinding separates the individual mineral particles from the waste rock and other mineral particles. The grinding is normally done in water with the resultant slurry called the pulp. Universal Tool Grinder / Universal Cutter Grinding Machine ...

Consulter un spécialiste

fr/rapport de projet media grinding.md at main hedaokuan/fr

Contribute to hedaokuan/fr development by creating an account on GitHub.

Consulter un spécialiste

Ultrafine grinding for improved mineral liberation in flotation ...

As the minerals industry is required to process increasingly complex, finely-grained ores, stirred mills are replacing ball mills for regrind applications in flotation circuits. Stirred mills are able to produce fine grind sizes in an energy efficient manner and without additional size classification. Laboratory grinding trials were conducted using two highspeed stirred

Consulter un spécialiste

Mineral processing Metallurgy, Crushing Grinding

mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue. It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgy. The primary operations are comminution and ...

Consulter un spécialiste

Ore Pretreatment Methods for Grinding: Journey and Prospects: Mineral ...

2018年6月18日 Mineral Processing and Extractive Metallurgy Review An International Journal Volume 40, 2019 - Issue 1. Submit an article Journal homepage. 766 Views 33 CrossRef citations to date ... Pretreatment of ores to improve energy efficacy of grinding has been explored for decades. However, many of these techniques are still at

Consulter un spécialiste

Fives Project management for cement and mineral grinding ...

Expert solutions, from equipment supply to complete plant delivery. Fives is renowned for its extensive experience in industrial plant project management and has installed more than 80 complete cement production lines around the world. We bring our original equipment manufacturer (OEM) expertise and our engineering, procurement and construction ...

Consulter un spécialiste

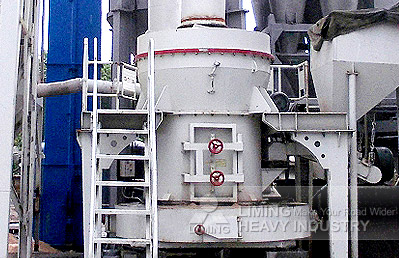

Fine grinding of industrial minerals - Mineral Processing

2008年12月1日 Fine grinding is a process stage that is necessary for all industrial minerals, some of which have to be ground to the submicron range. The following contribution provides an overview of the important industrial minerals, their manufacturing processes, the fineness requirements and the processes employed for dry and wet grinding. 1.

Consulter un spécialiste

Mineral Grinding Applications - Modern Process Equipment

Mineral Grinding. MPE grinders are unmatched in their efficiency and reliability. Our grinders are also corrosion-resistant and able to handle even the most corrosive mineral applications imaginable. Their high-yields are what make MPE grinders famous—so you’ll never worry about an unwanted fines problem. Grinding minerals can be hard on ...

Consulter un spécialiste

Method for crushing a mineral material in presence of at

The invention concerns a method for crushing a mineral material, which method comprises: -a step of providing said mineral material to be crushed and at least one grinding aid, said at least one grinding aid is chosen from organic plant materials in order to form a plant grinding aid, - a step of crushing said mineral material in the presence of said at least one

Consulter un spécialiste

Mineral Processing Project Plant and Mineral Grinding Plant

Chanderpur Works is the leading manufacturer supplier of mineral processing plant, mineral grinding plant mineral beneficiation plant. CPW provides services to mining industrial mineral companies for extracting, processing and transporting ores minerals. Since last few decades, CPG has been known for supplying highly efficient and ...

Consulter un spécialiste

Minerals Special Issue : Grinding Modeling and

It has been estimated that grinding consumes up to 4% of global electrical energy and accounts for more than 50% of the total energy used in mining operations. In addition, more than 90% of the total energy supplied in

Consulter un spécialiste

Metso to deliver grinding plant equipment to Mineral Park

2023年7月4日 Origin Mining is managed under the Waterton Global Resource Management, Inc. umbrella of investments. Mineral Park is in a historic, copper-rich mining district next to Kingman, Arizona. The total value of the order is €16 million. The order has been booked in Minerals’ second-quarter order intake.

Consulter un spécialiste

Improve the Fineness of the Mineral Aggregate in the Ball

2015年4月7日 Although in the same ball mill grind size, the useful minerals and gangue minerals monomer dissociation degree are not the same, but to make the most mineral monomer dissociation, which would inevitably mean that a small amount of the living body and over crushed minerals present in the grinding minerals, the impact on the

Consulter un spécialiste

Tuning the Morphology and Surface Property of Mineral

2017年11月18日 Grinding of minerals for particle size reduction and liberation is a prerequisite for successful mineral flotation separation and powder modification. Different grinding media produce mineral particles with different physical morphology and surface chemistry properties. Different mill particles expose different proportions of cleavage

Consulter un spécialiste

Effect of Dry Grinding on Kaolin Minerals Clays and Clay Minerals

The effect of dry grinding of kaolin minerals by a mechanical mortar was examined by x-ray, thermal, and electron microscopic methods. Base exchange capacity and apparent density were also measured. In the early stage of grinding, kaolin crystals cleave and fracture and then split into fine crystals which are considered unit crystallites. Such crystallites

Consulter un spécialiste

(DOC) CRUSHING DAN GRINDING (Pengolahan Mineral ...

Pengolahan mineral/bijih pada umumnya dilakukan secara basah. Pada umumnya operasi konsentrasi atau pemisahan mineral dilakukan dengan cara basah. Namun penggerusan klingker untuk menghasilkan semen selalu cara kering. 2. Penggerusan cara basah memerlukan energi lebih kecil dibanding cara kering. 3. Klasifikasi/sizing lebih mudah

Consulter un spécialiste

Intelligent Optimal-Setting Control for Grinding Circuits of Mineral ...

During the operation of a grinding circuit (GC) in mineral processing plant the main purpose of control and optimal operation is to control the product quality index, namely the product particle size, into its technically desired ranges. Moreover, the grinding production rate needs to be maximized. However, due to the complex dynamic characteristics between

Consulter un spécialiste

Enhanced Flotation of Dolomite Particles by Grinding with

2023年12月15日 In the field of mineral processing, the successful flotation of target minerals requires sufficient liberation through grinding. The aim of this paper is to compare and evaluate the performance of ball versus short cylindrical media for comminution of dolomite by point and line contact, respectively. The results of the grinding experiments

Consulter un spécialiste

North American Lithium Project, Quebec, Canada - Mining

2022年9月7日 The North America Lithium Project is located in the La Corne municipality, 60km from Val d’Or city in Quebec, Canada. It is situated in the Abitibi‐Témiscamingue region, 15km west of Barraute and 38km southeast of Amos. The property encompasses a contiguous group of 19 mineral claims and a mining lease that is valid until May 2032.

Consulter un spécialiste

Article aléatoire

- coût du projet de mini usine de ciment de 50 tpj en Inde

- portable de petite concasseur à machines à vendre

- fournisseurs de stations de concassage en algerie

- meules diamantees pour le broyage de verre

- mâchoire dentretien concasseur

- prix des machines de concassage de verre

- broyeur de pierres pathankot à vendre

- les investisseurs ont besoin

- fabricants mâchoire de concasseur mobile en inde

- la machine de concassage de pierres en Corée

- porkert moulin de broyage de cuisine

- timming convoyeur indonesie

- excel 2522 concasseur à vendre

- petite echelle de minerai d argent concasseur minier

- automatisés fabricants de machines de chronométrage en Chine

- fabricants de ciment moulins billes

- delta asaba acierie nigeria

- application de la ligne de production de sable

- Concasseur de pierre dans Andhrapradesh

- concasseur à machines suspendu

- concasseur à machines pour usine de gypse

- les broyeurs a boulets Table

- utilisé traitement de la silice Algérie

- trotteuse concasseur à machines allemand à vendre

- universelle fraisage nouvelle

- concasseur à cône pour embaucher uk

- triturador de biomassa

- minerai de fer usines de bouletage en Maroc

- sable pour filtre eau youtub

- utilisations typiques de quartzite